OXO

Accurate

Position detection up to 1 mm

Real Time

0.08 second delay

User-Friendly

Easy configuration and calibration

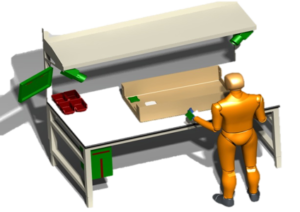

OXO

Thanks to the cameras and special equipment placed in the hands of the operators working on the assembly lines of the factories or on the assembly devices they use, OXO detects position at millimeter level, and ensures validity of the process steps by monitoring and controling them.